Tube Production

Schöler, As a leading supplier of production equipment for thin-walled tube and profile manufacturing in the heat exchanger industry, we provide a diverse array of efficient solutions. Our specialty lies in creating folded and seam-welded geometries. This encompasses folded profiles for heat exchanger production, including snap over, clinched, and B-type designs, as well as multiport profiles suitable for the air conditioning industry. Moreover, we excel in manufacturing seam-welded profiles from aluminum or brass, available in flat oval or rectangular shapes with hourglass and dimple designs, all achieved at maximum production speeds. For enhanced efficiency, Schöler has pioneered a unique machine and tool quick-change concept.

Our Expertise Covers:

- Folded Tube/Profile Geometries

- Seam-Welded Tube/Profile Geometries.

Multiport Tube Folding Machine RFL

Folded multiport tubes made of several strips

Folded multiport tubes, constructed from multiple strips, are gaining traction in heat exchanger innovation. They surpass extruded profiles with enhanced corrosion resistance and expanded product design options, boasting improved strength data. By employing just two strips, varying material thicknesses can be achieved for tube webs and outer walls, unlocking a broad range of geometries previously unavailable with traditional profiles.

Highlights of the RFL tube folding machines

The RFL tube folding machines are revolutionary for 24/7 production of folded multiport tubes. They embody Schoeler’s signature features like compact design, modular construction, tool change efficiency, and an intuitive HMI interface. These machines handle key aspects in the production of 2- or 3-piece multiport tubes, including integrated degreasing, fluxing, distortion-free high-speed cutting, and automated packaging.

Tube Folding Machine RF

Unrivalled high quality standards

The latest RF tube folding machines showcase Schoeler’s decades-long expertise in thin-walled, roll-formed tube profiles. This new RF generation boasts high production speed, enhanced precision, and maximum flexibility and efficiency. Its clever modular design allows for excellent customization. The updated appearance reflects Schoeler’s commitment to precision, value, and ergonomics in tube folding machines.

Efficient profile roll forming design

Each tube profile is unique, demanding a dependable roll design process for swift and efficient execution. Schoeler engineers possess these crucial skills. Our three-stage process, bolstered by diverse simulation methods, ensures reliable design outcomes. Identifying critical forming stages in the design phase allows for timely adjustments, while early insights into material stress curves minimize future production issues, saving time and cutting development costs.

Tube Welding Machine RHF

Well-equipped for new market requirements

Our RHF tube welding machines are born from decades of expertise, delivering unmatched productivity and adaptability. With speeds reaching 200 m/min and the capacity to produce 500 tubes per minute, these machines handle tube dimensions up to 105mm in height and 10mm in width.

What sets our machines apart is their flexibility. They can be easily upgraded or reconfigured at any time, thanks to specially designed additional applications and a standardized framework. The modular design allows you to scale automation and production speed to your evolving needs, turning a compact entry-level model into a 24/7 automated system with full product packaging capabilities.

If you have unique ideas, our team is ready to provide customized solutions in electronics, mechanics, and service to bring your vision to life and ensure your success.

Cut Off Unit – RS Series

Highest cut rate – minimal cut length tolerances

Schoeler’s cut-off units have been the gold standard in high-end tube production for decades. They excel in delivering precise profile cuts with minimal length tolerances and unmatched cutting speed.

Our forward-thinking R&D team is always at the forefront of customer and market demands. The latest generation of Schoeler cut-off units, equipped with the innovative flying cut mechanism, guarantees precise profile cutting at any production speed. This technology is now a standard feature in all our new tube production machines and can also be seamlessly integrated into existing Schoeler machines or third-party equipment.

It replaces the RS 100, RS 200, and RS 300 series, with ongoing spare parts and service support. The electronic solution delivers precise cutting performance by directly controlling servo controllers and motors via tailored computer hardware and algorithms, suitable for various end products.

- RS 800/RS 830: Vertically standing longitudinal seam-welded tubes (radiator, charge air cooler, and oil cooler) cut at speeds up to 200 m/min.

- RS 801/823: Horizontally positioned B-type folded or multi-chamber tubes cut at 500 cuts per minute, with a speed of 200 m/min.

- RS 841: Utilizes patented cutting to separate two-part multi-chamber tubes with an inner fin made of ultra-thin aluminium strip (minimum 0.07 mm thickness) enclosed by a folded B-type or Snap Over tube.

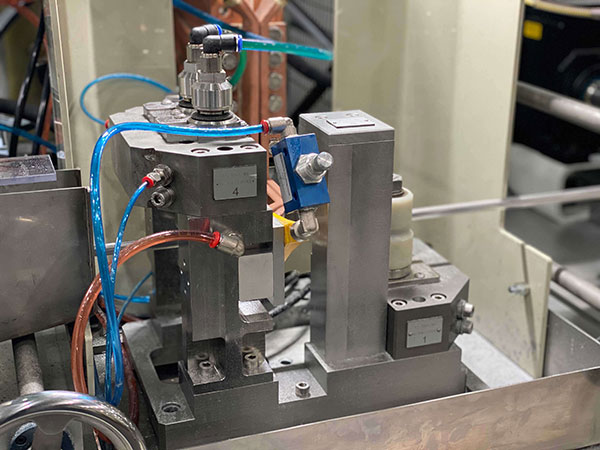

Burst pressure tester BPT

Precise and Reliable

The semi-automatic burst pressure tester BPT 200 is the optimal solution for visual weld seam leak testing as well as burst pressure determination of seam-welded tubes. Prove the quality of your welded tubes with the help of our burst pressure test equipment.

Some of Our Prestigious Customers