Assembly & Handling

Our engineers prioritize precision and efficiency in crafting custom system solutions for core assembly, serving automotive and HVAC/R industries. These solutions deliver high-performance assembly and handling, catering to various automation levels, product dimensions, and applications. Our focus on production speed and quick-change capabilities ensures maximum flexibility and efficiency for our customers.

- Semi-automatic core assembly systems

- Automatic and fully automated core assembly lines

- Automatic HVAC/R coil assembly lines

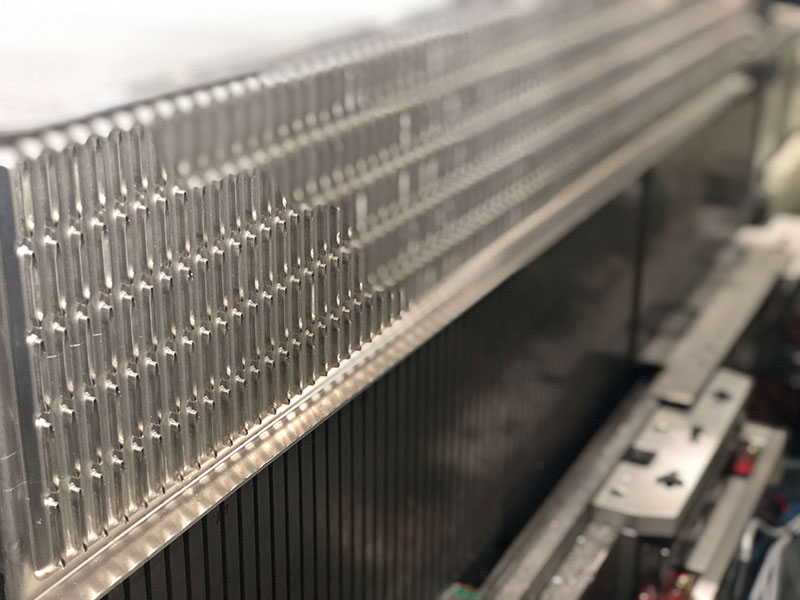

Semi-automatic core building ZZH

Flexible multi-row core building

The ZZH semi-automatic assembly lines excel in rapid tool changes, enhancing efficiency for diverse product ranges. Whether it’s a single-row automotive radiator or a multi-row truck system, ZZH ensures top-notch flexibility and productivity. You can enhance automation with features like tube or component allocation from magazines, single to six-row heat exchanger configurations, individually adjustable tube end flaring, or assisted heat exchanger removal. This guarantees outstanding repeatability and consistent product quality in a semi-automatic assembly process, free from operator dependency.

Automatic core assembly line ZZA

Assembly lines for radiators, condensers, charge air coolers

The ZZA 300, 400, and 600 series core assembly lines craft standard-size radiators, condensers, and charge air coolers for automotive and heavy-duty applications. These machines prioritize precision, flexibility, and rapid model/product switching. Automatic core assembly lines, designed for medium to high production volumes, seamlessly assemble heat exchanger components, streamlining the core’s transition to the brazing process, while minimizing operator involvement.

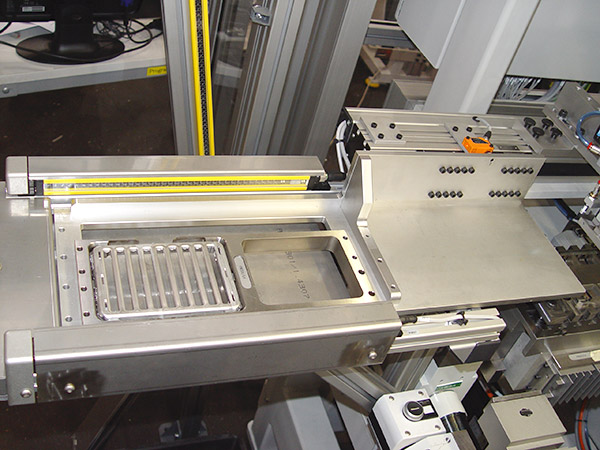

Automatic core assembly line – compact

Assembly lines for compact charge air coolers

The ZZA 800 core assembly lines excel in efficiently producing compact intercoolers at medium to high production rates. They expertly automate the assembly of heat exchanger components, ensuring a seamless transition to the brazing process. Our focus on optimization centers on the automated production of small product sizes, allowing us to achieve maximum efficiency. Depending on specific requirements, we offer varying degrees of automation to perfectly align with your manufacturing needs and speed.

Some of Our Prestigious Customers