Fin Production

As an automotive and HVAC/R industry partner, we specialize in crafting precision fin geometries. Our advanced technology ensures efficient manufacturing with specialized tools and cutting-edge materials like sintered metals. We work with various materials like aluminum, steel, carbide, and copper strips, offering single or multi-track forming processes to suit your needs. Your vision, our expertise.

Fin Rolling Machine

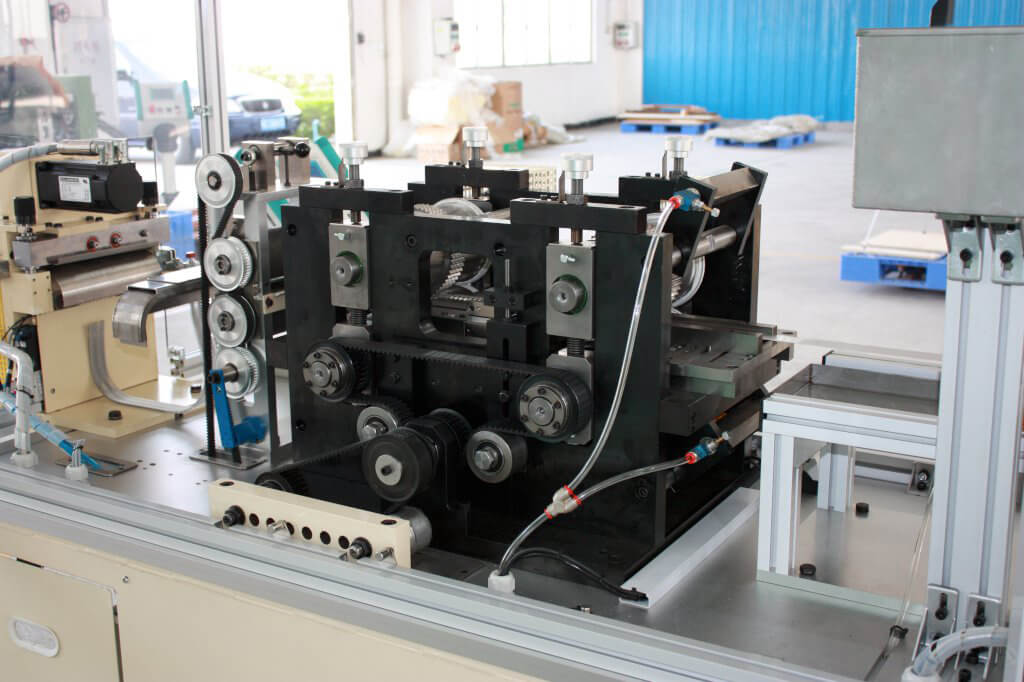

Schoeler caters to both OEM and aftermarket heat exchanger fin production. Our LW 100 fin rolling machine adapts OEM-grade functions and components for aftermarket needs, ensuring top-quality results on compact, user-friendly equipment with an excellent price-performance ratio.

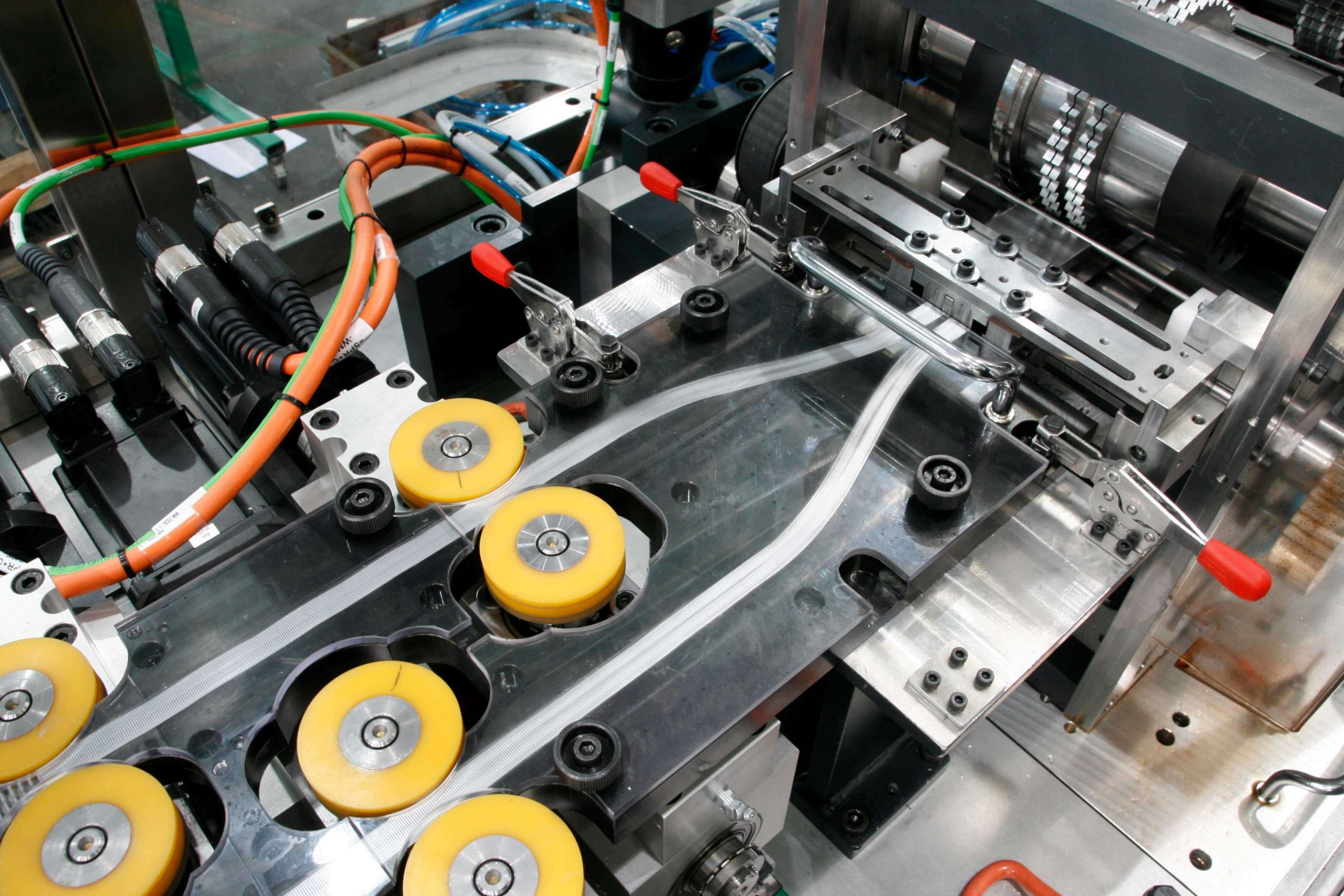

Versatile, precise and highly efficient

Our stable machine concept guarantees precision, from safety enclosures to tool cassettes, marking a milestone in sophisticated machine design.

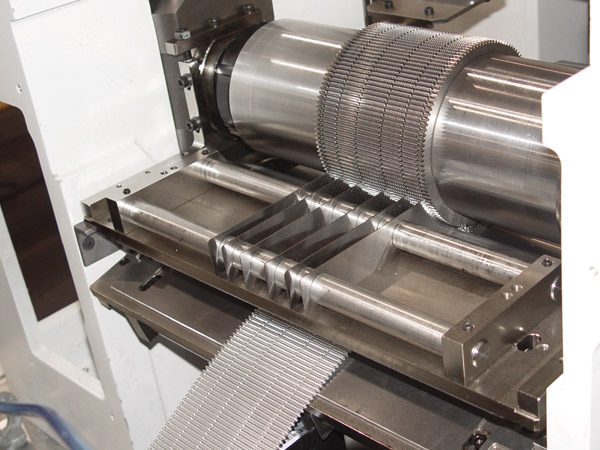

The forming rollers are the heart of the machine

We excel in forming roll design, 3D simulations, and extensive experience in profile and louver grinding for roller discs.

Our advanced material databases and manufacturing processes enable precise production of complex rolled profiles.

Fin Press

Schoeler specializes in producing unique fin geometries, such as square-wave flanks or flat-top designs, using pressing rather than traditional rolling methods. From prototyping to mass production, we provide tailored manufacturing solutions for various sectors, including automotive, construction machinery, and aviation. Our SL type presses offer quick-change capability, precision, and high output, allowing for the rapid production of diverse fin types with consistent quality in minutes.

Special fin forming machines

Highest productivity and maximum flexibility

Schoeler special fin machines are used in the automotive and HVAC/R sectors to produce special fin geometries for applications such as oil coolers, charge air coolers, generator radiators, etc. Whenever the standard rolling process reaches its limits, the special rolling processes open up new horizons through multi-stage rolling processes or combinations of rolling and pressing. Even the most advanced fin geometries can be produced with the highest quality and speed.

Some of Our Prestigious Customers